- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

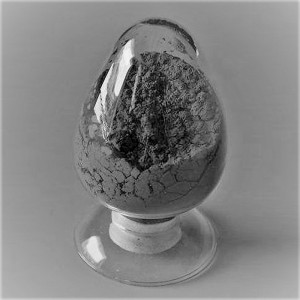

Tellurium Copper Alloy

Tellurium Copper Alloy, by gradually adding designed weight percent of 99.99% pure tellurium into molten commercial pure 9.99% copper cathode in the power-frequency induction furnace, and meanwhile a certain of phosphorus as the deoxidant and a little microelements needed is added into the molten liquid to get desirable tellurium copper alloy.

Being superior free cutting performance , which enabling a much higher machining speed than that is possible with pure copper, the machinability scale is rated as 90, both cold working or hot forming are practicable, and with good arc-resistance performance, hydrogen embrittlement, higher electric conductivity(90% IACS) and thermal conductivity, and anti- corrosiveness, Tellurium Copper Alloy (C14500,CuTeP) is mainly used for welding (hydrogen cutting, acetylene cutting and argon-arc welding tool), chemical industry and mineral machinery such as automobile carburetor nozzle, welding torch tips, gas cutting nozzles, storage battery head and air conditioning connector, electrical switches on power semiconductors, transformer & circuit breaker terminals, switch gears and valve manufacturing etc.

All products conform to RoHS regulations.

Details

Tags

Technical Specification

|

No. |

Item |

Standard Specification |

|||

|

1 |

Grade |

Te |

Re |

P |

Cu |

|

2 |

Te-Cu |

0.2-0.35% |

0.03-0.05% |

- |

balance |

|

3 |

Te-P-Cu |

0.4-0.70% |

- |

0.004-0.012% |

balance |

|

4 |

Hardness |

H04, H02, O60 |

|||

| Tensile Strength |

265 Mpa Min |

||||

| Elongation |

8% Min |

||||

| Electrical Conductivity |

90% IACS Min |

||||

| Machinability Rate |

90 Min [based on HPb 63-3(C36000)] |

||||

|

5 |

Size | Cast D90 mm × L (0.25-5) m, Extruded D(5-40) mm×L (0.25-5) m | |||

|

6 |

Standard |

ASTM-C14500/ GB-QTe0.5/ JIS-C1450/ DIN-CuTeP/ BS-C109 |

|||

|

7 |

Packing |

In plywood case |

|||

Procurement Tips

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- Quality Inspection Including XRD/SEM/ICP/GDMS etc

- Full Scope of Trade Terms CPT/FOB/ CFR/CIP By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- ISO9001:2015 Certified & Rohs/REACH Regulations Approval

- Non-Disclosure Agreements

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu