- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

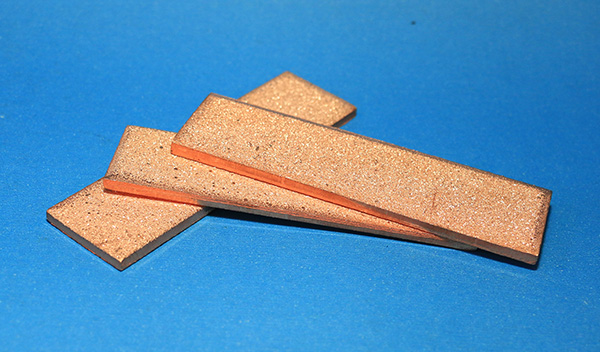

High Purity Copper

Description

High Purity Copper 5N 6N, a reddish purple color metal material with atomic weight 63.55, melting point 1083.40°C and density 8.96g/cm3, has characteristic of malleable and ductile, excellent conductor of heat, robust construction and less oxidation. High Purity or Ultra Purity Copper can be obtained to more than 99.999%, 99.9999% purity by purification process of vacuum smelting and zone-refining, which is uniform equiaxed grain, consistant microstructure, corrosion resistance, low softening temperature and good surface performance. High Purity Copper 5N 6N at Western Minmetals (SC) Corporation with 99.999% and 99.9999% purity can be delivered in various forms of bar, ingot, plate and nugget in package of composite aluminum bag with carton box outside, or as customized specification to reach the perfect solution.

Applications

High Purity Copper is primarily used to prepare high purity copper targets for functional coating of components, for high purity copper tubes, microelectronics, TFT-LCD, integrated circuits ICs, to make high purity copper rod by vacuum continuous casting, to prepare bonding wires for electronic packaging and high quality audio cable etc. High Purity Copper 5N 6N can also be directly used as additive element in the development of super alloy and new alloy in aviation and aerospace and atomic industry, as well as high purity copper foil preparation by standard machining process for shielding material of atomic reactor. Generally, high purity copper is widely used in the manufacturing of electronic semiconductor devices and elements, large scale electron tubes, special alloy materials, sputtering targets, rectifying elements, biologic medicine and calibration specimens in metal analysis field and electronic chemical industry.

Details

Tags

Technical Specification

Cu

|

Atomic No. |

29 |

|

Atomic Weight |

63.55 |

|

Density |

8.96g/cm3 |

|

Melting Point |

1083.4°C |

|

Boiling Point |

2567°C |

|

CAS No. |

7440-50-8 |

|

H.S Code |

7403.1111.90 |

| Commodity | Standard Specification | |||

| Purity | Impurity (ICP-MS or GDMS Test Report, PPM Max each) | |||

| High Purity Copper |

5N | 99.999% | Ag/Fe/Ni/Co/Zn/Si 1.0, Bi/Mg/Mn/Pb/Se/Sb 0.5 | Total ≤10 |

| 6N | 99.9999% | Bi/Fe/Sb/Co/Zn 0.1, Mg/Mn/Pb/se/Ni 0.05 | Total ≤1.0 | |

| Size | 80x40x4mm bar or small round nugget or cylinder | |||

| Packing | 1kg in plastic bag, carton box outside | |||

| Remarks | Customized specification is available upon request | |||

High Purity Copper 99.999%, 99.9999% is primarily used to prepare high purity copper targets for functional coating of components, for high purity copper tubes, microelectronics, TFT-LCD, integrated circuits ICs, to make high purity copper rod by vacuum continuous casting, to prepare bonding wires for electronic packaging and high quality audio cable etc. High Purity Copper can also be directly used as additive element in the development of super alloy and new alloy in aviation and aerospace and atomic industry, as well as high purity copper foil preparation by standard machining process for shielding material of atomic reactor.

Generally, high purity copper is widely used in the manufacturing of electronic semiconductor devices and elements, large scale electron tubes, special alloy materials, sputtering targets, rectifying elements, biologic medicine and calibration specimens in metal analysis field and electronic chemical industry.

Procurement Tips

- Sample available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facility

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment

High Purity Copper

related products

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu