- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Details

Tags

Tantalum | Zirconium

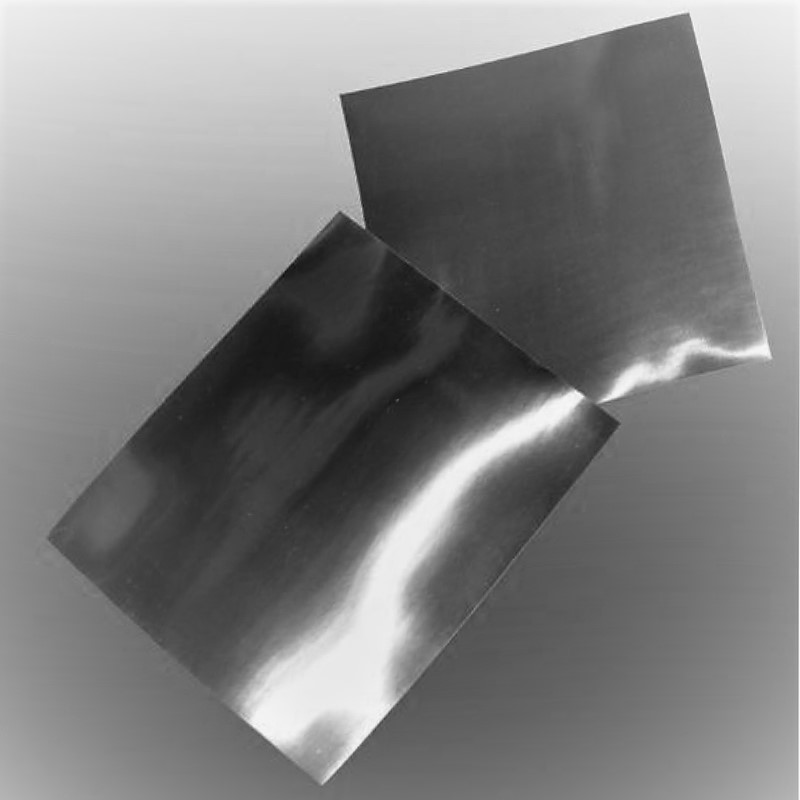

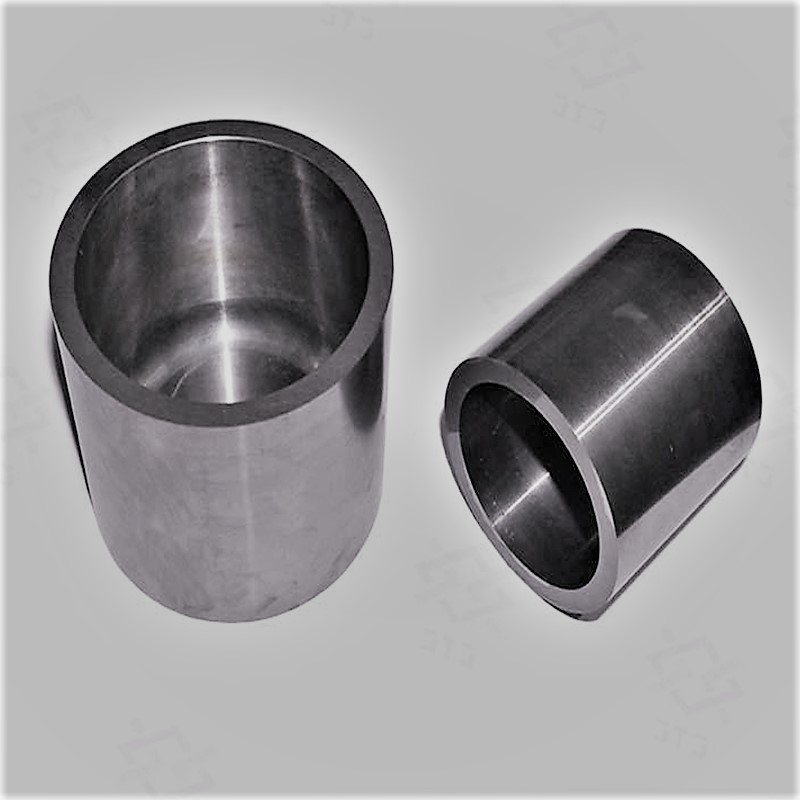

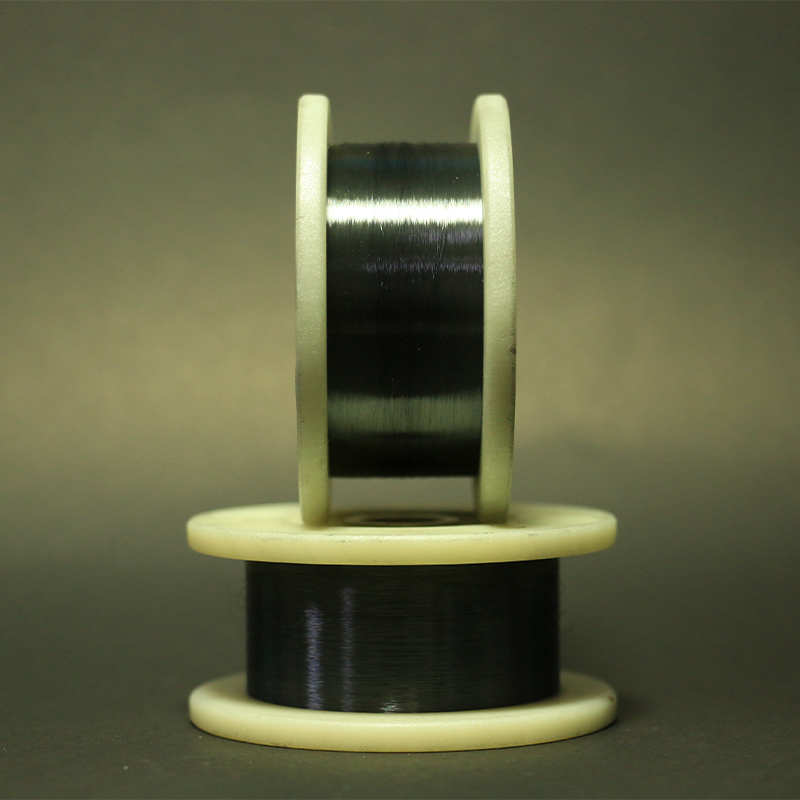

Tantalum at Western Minmetals (SC) Corporation can be delivered in size of rod, plate, sheet, powder, wire, foil, tube and customized product for different applications.

Zirconium and zirconium alloy have good plasticity and can be fabricated in the form of pipe, plate, bar, tube, rod, powder, foil and wires for different application.

| No. | Item | Standard Specification | ||

| Tantalum Ta | Zirconium Zr | |||

| 1 | Purity | ≥99.9% | Zr+Hf ≥99.4% Hf 2.0 | |

| 2 | Impurity PCT Max each | H 0.008, Cu/W/Mo/K0.001, Nb/Cr 0.003, C/Fe/Ti/Al/Mn/Na 0.005,N 0.015, O 0.25 | Ni/Mn/N 0.01, Pb/Ti 0.005, Cr 0.02, O/Fe 0.1, | |

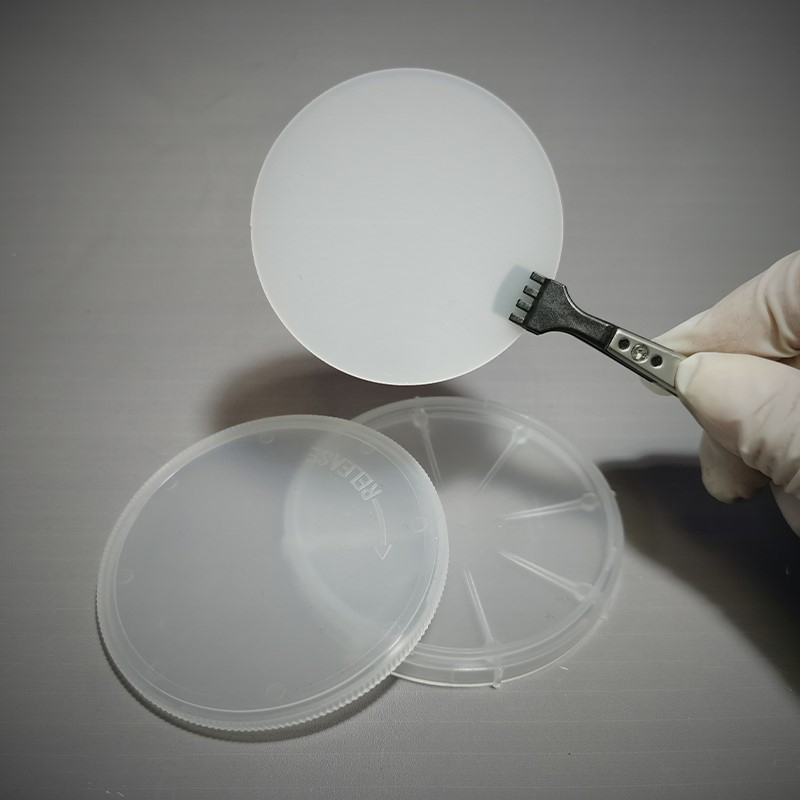

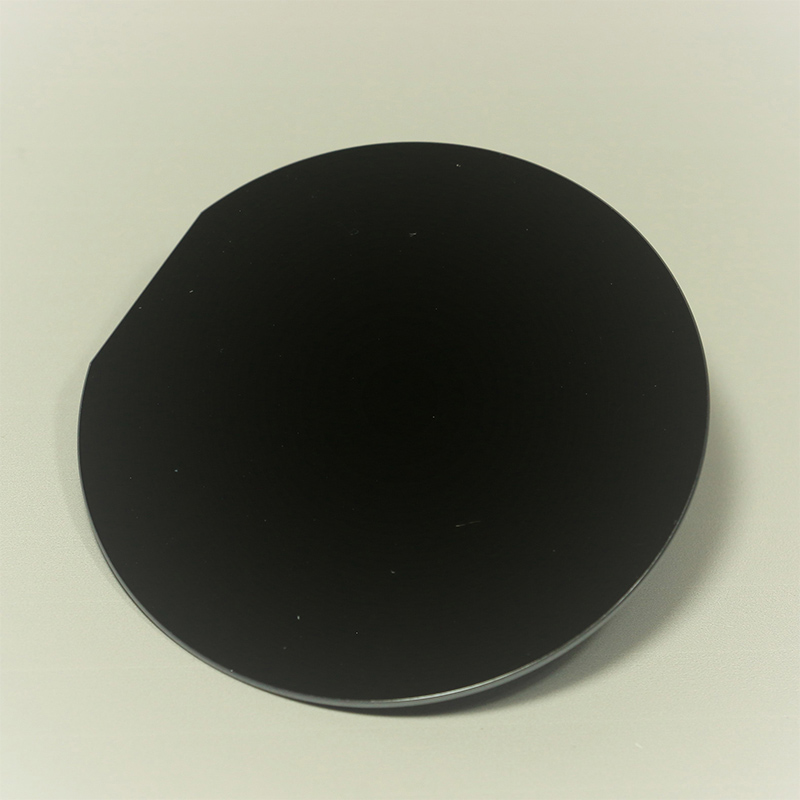

| 3 | Size | Plate | (1.0-5.0)×1000×L | >1.0×1000×L |

| Sheet | (0.1-1.0)×650×L | (0.1-0.9) ×600×L | ||

| Strip | (0.01-0.09)×110×L | - | ||

| Foil | (0.5-30)×(0.2-5.0)×L | (0.01-0.09) ×110×L | ||

| Rod | D(3.0-45)×L | D(3.0-100)xL | ||

| Wire | D0.1-D3.0 | D0.1-D3.0 | ||

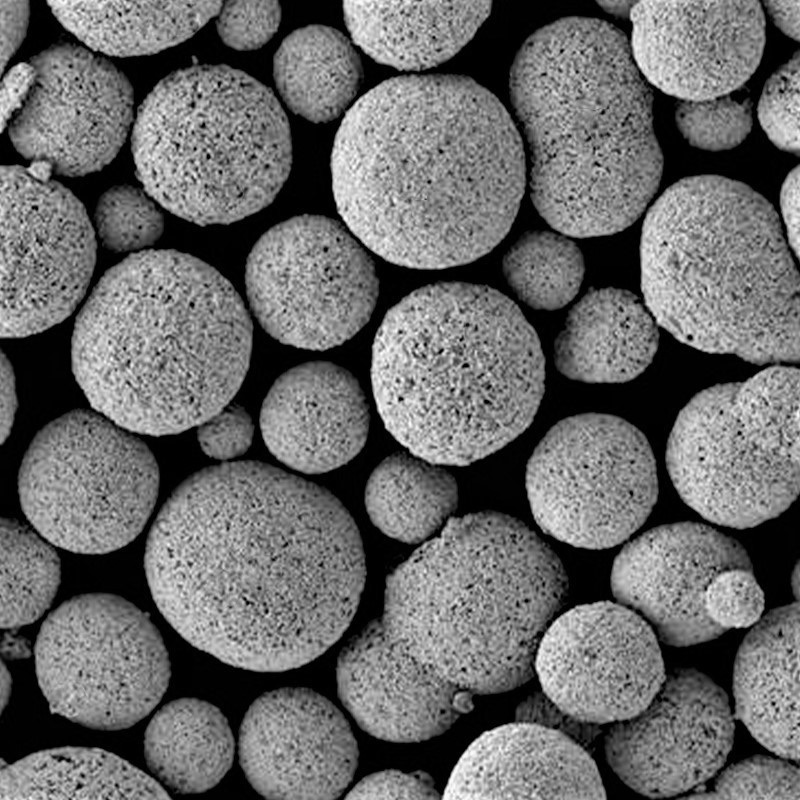

| Powder | -100, -200, -300mesh | -100,-200,-300mesh | ||

| Tube | D(0.5-30)×(0.2-5.0)×L | (22.0-150)×(22.0-150) ×(0.8-3.0)×L, D(3.0-200)×(0.15-5.0)×L | ||

| Target | Available Upon Request | Available Upon Request | ||

| 4 | Packing | 25/50kgs in iron drum, or in plywood case | ||

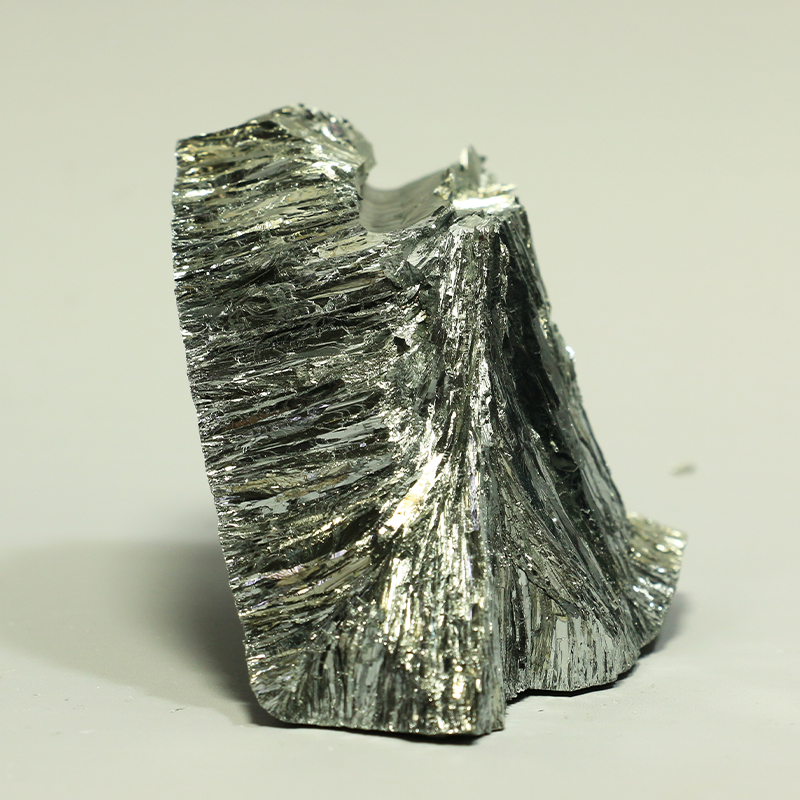

Zirconium Zr, a kind of light gray and high melting point rare metal, CAS 7440-67-7, melting point 1852℃, boiling point 4377℃, mass 91.224, density 6.49g/cm3, has excellent corrosion resistance to a variety of acids, alkali and salts, but soluble in hydrofluoric acid and aqua regia. Zirconium is widely used in the fields of aerospace, military, electronic industry, nuclear reaction and atomic energy to make corrosion-resistant parts, special high strength and superalloy materials.

Zirconium has strong affinity with oxygen, nitrogen and other gases, and can be used as hydrogen storage materials in the electric vacuum industry which electronic tubes and other electric vacuum instruments with high vacuum are widely made to improve their quality and prolong their service time. Zirconium is used for deoxidation, nitrogen removal and sulfur removal in metallurgical industry to greatly improved the hardness and strength of steel for the production of armor steel, stainless steel and heat-resistant steel. Being good corrosion resistance, moderate mechanical properties, low atomic thermal neutron absorption cross section and good compatibility with nuclear fuel, It is used in nuclear energy industry as structural material, cladding and pressure pipe of reactor core

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- ISO9001:2015 Certified

- CPT/CIP/FOB/CFR Terms By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- Quality Inspection By Sate-of-the-art Facilit

- Rohs/REACH Regulations Approval

- Non-Disclosure Agreements NDA

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment