- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Details

Tags

| No. | Items | Standard Specification | ||

| 1 | General Characteristics | |||

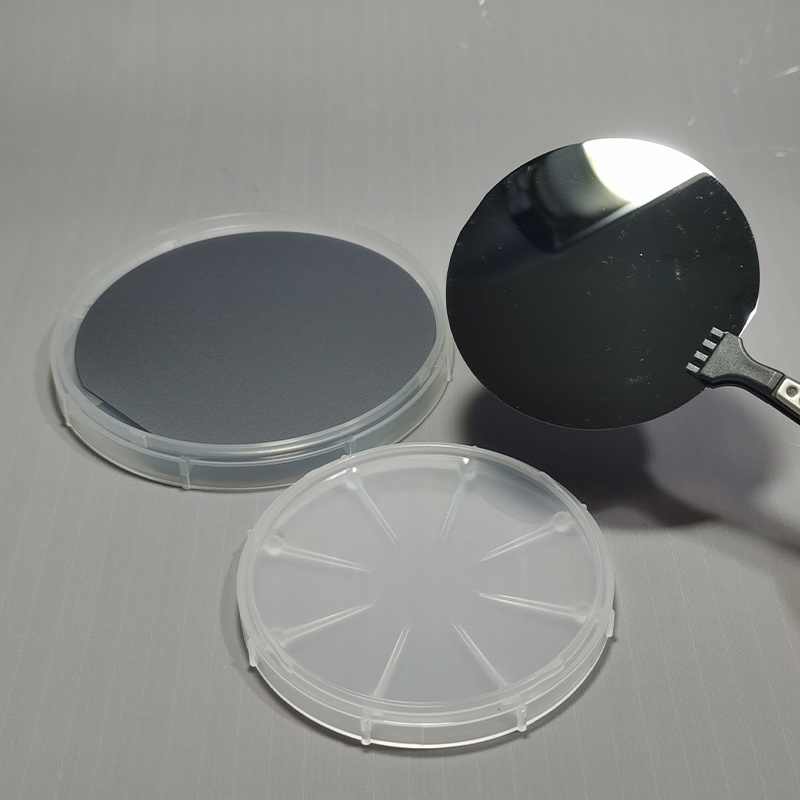

| 1-1 | Size | 4″ | 5″ | 6″ |

| 1-2 | Diameter mm | 100±0.5 | 125±0.5 | 150±0.5 |

| 1-3 | Orientation | <100>, <111> | <100>, <111> | <100>, <111> |

| 2 | Epitaxial Layer Characteristics | |||

| 2-1 | Growth Method | CVD | CVD | CVD |

| 2-2 | Conductivity Type | P or P+, N/ or N+ | P or P+, N/ or N+ | P or P+, N/ or N+ |

| 2-3 | Thickness μm | 2.5-120 | 2.5-120 | 2.5-120 |

| 2-4 | Thickness Uniformity | ≤3% | ≤3% | ≤3% |

| 2-5 | Resistivity Ω-cm | 0.1-50 | 0.1-50 | 0.1-50 |

| 2-6 | Resistivity Uniformity | ≤3% | ≤5% | - |

| 2-7 | Dislocation cm-2 | <10 | <10 | <10 |

| 2-8 | Surface Quality | No chip, haze or orange peel remains, etc. | ||

| 3 | Handle Substrate Characteristics | |||

| 3-1 | Growth Method | CZ | CZ | CZ |

| 3-2 | Conductivity Type | P/N | P/N | P/N |

| 3-3 | Thickness μm | 525-675 | 525-675 | 525-675 |

| 3-4 | Thickness Uniformity max | 3% | 3% | 3% |

| 3-5 | Resistivity Ω-cm | As required | As required | As required |

| 3-6 | Resistivity Uniformity | 5% | 5% | 5% |

| 3-7 | TTV μm max | 10 | 10 | 10 |

| 3-8 | Bow μm max | 30 | 30 | 30 |

| 3-9 | Warp μm max | 30 | 30 | 30 |

| 3-10 | EPD cm-2 max | 100 | 100 | 100 |

| 3-11 | Edge Profile | Rounded | Rounded | Rounded |

| 3-12 | Surface Quality | No chip, haze or orange peel remains, etc. | ||

| 3-13 | Back Side Finish | Etched or LTO (5000±500Å) | ||

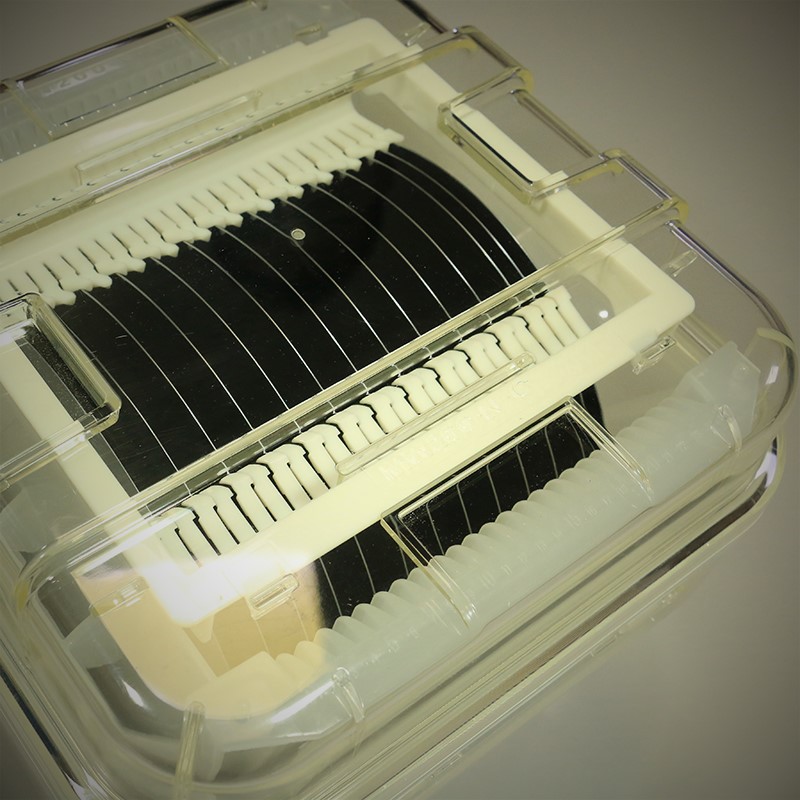

| 4 | Packing | Cassette inside, carton box outside. | ||

| Symbol | Si |

| Atomic Number | 14 |

| Atomic Weight | 28.09 |

| Element Category | Metalloid |

| Group, Period, Block | 14, 3, P |

| Crystal structure | Diamond |

| Color | Dark gray |

| Melting Point | 1414°C, 2577.2°F, 1687.15 K |

| Boiling Point | 3265°C, 5909°F, 3538.15 K |

| Density at 300K | 2.329 g/cm3 |

| Intrinsic resistivity | 3.2E5 Ω-cm |

| CAS Number | 7440-21-3 |

| EC Number | 231-130-8 |

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- Quality Inspection Including XRD/SEM/ICP/GDMS…

- Full Scope of Trade Terms CPT/CIP/FOB/CFR By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- ISO9001:2015 Certified

- Rohs & REACH Regulations Approval

- Non-Disclosure Agreements

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment