- info@matltech.com

- E2-1-1011 Global Center, No.1700 Tianfu Avenue North, Chengdu 610041, China.

Online Exporter High Purity Selenium Sulfide Lump 99.999% - Titanium Carbide TiC | Vanadium Carbide VC – WMC

Details

Tags

Vanadium Carbide VC and Titanium Carbide TiC at Western Minmetals (SC) Corporation can be delivered in size of powder 0.5-500 micron or 5-400 mesh or as customized specification, package of 25kg, 50kg in plastic bag with iron drum outside.

| No. | Item | Standard Specification | |||||||

| 1 | Products | Cr3C2 | NbC | TaC | TiC | VC | ZrC | HfC | |

| 2 | Content % | Total C ≥ | 12.8 | 11.1 | 6.2 | 19.1 | 17.7 | 11.2 | 6.15 |

| Free C ≤ | 0.3 | 0.15 | 0.1 | 0.3 | 0.5 | 0.5 | 0.3 | ||

| 3 |

Chemical Impurity PCT Max each |

O | 0.7 | 0.3 | 0.15 | 0.5 | 0.5 | 0.5 | 0.5 |

| N | 0.1 | 0.02 | 0.02 | 0.02 | 0.1 | 0.05 | 0.05 | ||

| Fe | 0.08 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | ||

| Si | 0.04 | 0.01 | 0.01 | 0.02 | 0.01 | 0.005 | 0.005 | ||

| Ca | - | 0.005 | 0.01 | 0.01 | 0.01 | 0.05 | 0.05 | ||

| K | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | ||

| Na | 0.005 | 0.005 | 0.005 | 0.01 | 0.01 | 0.005 | 0.005 | ||

| Nb | 0.01 | - | 0.01 | 0.01 | 0.01 | 0.005 | 0.005 | ||

| Al | - | 0.005 | 0.01 | - | - | - | - | ||

| S | 0.03 | - | - | - | - | - | - | ||

| 4 | Size | 0.5-500micron or 5-400mesh or as customized | |||||||

| 5 | Packing | 2kgs in composite bag with iron drum outside, 25kgs net | |||||||

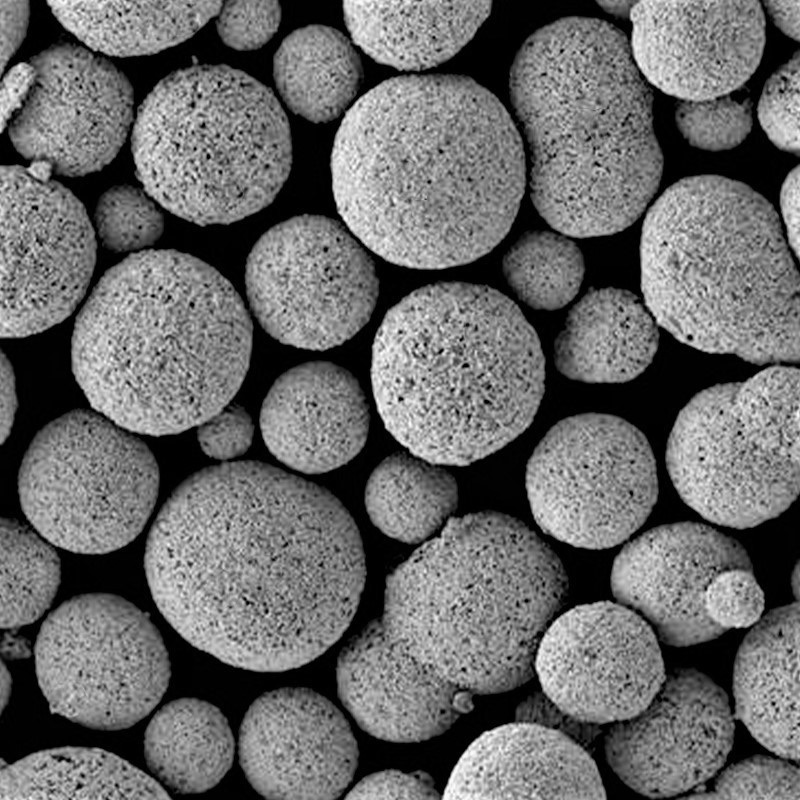

Vanadium Carbide VC, a kind of transition metal carbide, gray metallic powder with cubic lattice system structure of NaCl type, melting point 2810°C, boiling point 3900°C, density 5.41g/cm3, molecular weight 62.95, Soluble in nitric acid, insoluble in cold water, hydrochloric acid and sulfuric acid, and melting with potassium nitrate, is of chemical stability and resistant to chemical corrosion. ols.

Vanadium Carbide is used as additive to fine the WC crystalline grain for improving the property of alloy in the production of cemented carbide. With high hardness, melting point, high temperature strength and other general characteristics of transition metal carbides, as well as good conductivity and thermal conductivity, so it is widely used in iron and steel metallurgy for Vanadium Steel melting to improve the comprehensive properties of steel, such as wear resistance, corrosion resistance, toughness, strength, ductility, hardness and thermal fatigue resistance. Beside It finds more applications in thin film, target material, welding material, cemented carbide, cermet, electronic products, catalysts and high temperature coating materials in different cutting and wear-resistant to

- Sample Available Upon Request

- Safety Delivery of Goods By Courier/Air/Sea

- COA/COC Quality Management

- Secure & Convenient Packing

- UN Standard Packing Available Upon Request

- Quality Inspection Including XRD/SEM/ICP/GDMS etc

- Full Scope of Trade Terms CPT/FOB/ CFR/CIP By Incoterms 2010

- Flexible Payment Terms T/T D/P L/C Acceptable

- Full Dimensional After-Sale Services

- ISO9001:2015 Certified & Rohs/REACH Regulations Approval

- Non-Disclosure Agreements

- Non-Conflict Mineral Policy

- Regular Environmental Management Review

- Social Responsibility Fulfillment